What factors contribute to the control accuracy of metal etching? This article will provide you with a detailed explanation. The issue of control accuracy in metal etching has always been the most important and difficult problem to overcome in the chemical etching industry. There are inevitably issues with the length of time and material thickness when using chemical methods to shape products. Therefore, the accuracy of metal etching will be affected by the following conditions

1. The control accuracy of metal etching is related to the material of the metal. Different materials have varying etching effects and speeds under different chemical conditions. Stainless steel and aluminum, under the same conditions, can have significant differences in precision. Generally, stainless steel and copper materials are etched using ferric chloride acidic substances, while aluminum materials are both acidic and sensitive to alkali. Under the same etching conditions, the precision of stainless steel will be higher

2. The control accuracy of metal etching is related to the chemical solution formula used for etching. The formulation of chemical etching agents for the same material, such as concentration, temperature, etc., has a direct relationship.

3. The control accuracy of metal etching is also related to exposure. The magnitude of exposure energy can cause different reactions in the photosensitive adhesive layer. Insufficient exposure energy can cause line shedding. Exposure energy is high, which can easily lead to exposure death, difficulty in developing the adhesive layer, and rough graphics.

4. The control accuracy of metal etching is related to development. The proportion of developing solution will affect whether the photosensitive adhesive layer is thoroughly cleaned, ultimately resulting in different line errors during the etching process.

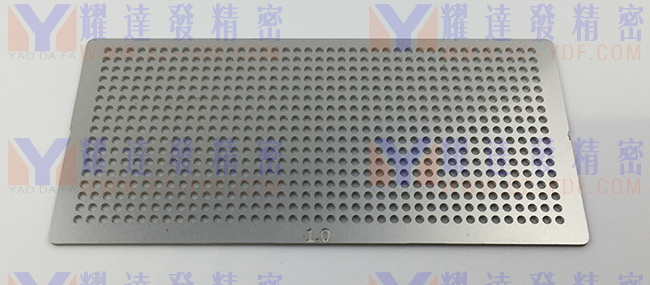

5. The control accuracy of metal etching is related to the equipment used. The quality and service life of equipment are directly related to the accuracy of the products produced. Accurate equipment, stable system operation, and uniform spray system all have a direct impact on the accuracy of the product. Yaodafa Precision has introduced imported etching equipment to ensure that the precision of the products produced meets customer requirements perfectly, and stable mass production is achieved.

Complete set of etching processing equipment

6. The control accuracy of metal etching is affected by the applied photosensitive oil. Good photosensitive ink will have better development effect, and the thickness of the coating will also affect the etching accuracy.

Film coating equipment, automated

7. The control accuracy of metal etching is also affected by the initial template production. Zhuolida currently uses film templates and glass templates, both of which have a direct impact on the accuracy of exposure. The expansion coefficient of the film template is larger, which affects the accuracy of exposure. However, our glass exposure template can basically ignore errors and is fully automated production, avoiding the influence of manual operation.

Roll to roll exposure machine

8. The control accuracy of metal etching is related to whether it is a dust-free purification workshop. Because all processes require preventing dust from falling onto the steel surface of the product. If there is dust adhering to the surface, etching will result in white spots and corrosion pits on the product. If a crack is formed at the edge of the product, it will seriously affect the appearance and accuracy of the product! Yaodafa Precision Construction''s dust-free purification vehicle has reached the thousand level and is the preferred factory for serving high-end metal etching processing. Ensure the precision of metal etching meets the polite requirements.

.png)

Yaoda Precision adjusts the control accuracy of metal etching through a complete set of control and process equipment. We will explain in detail the factors that make up the control accuracy of metal etching, and provide the most detailed explanation of the factors that make up the control accuracy of metal etching

Richard.Liu/刘家成

+86 180 2542 8186(wechat)

深圳市耀达发精密科技有限公司

Shenzhen Yaodafa Precision Technology Co., Ltd.

E-mail: LJC@SZ-YDF.COM

English website:http://www.ydf-seiko.com/

Shenzhen Address:203, Building 13, Dawangshan Second Industrial Park, Shajing Street, Bao''an District, Shenzhen , China

——Design and sales of metal accessories, metal finished products

——One Stop Solutions Provider Of Your Metal Precision Parts

Next:How to drill a 0.2 holePrevious:Etching of lead frame

正在载入评论数据...

.png)