Micro hole processing is a difficult technique in traditional processing, which falls between traditional processing and microfabrication. In many research laboratories in various countries, there is research in this area. Although lasers can be used to process holes with very small diameters, their biggest drawback is that high-temperature cutting changes the material properties and can easily cause product deformation due to high temperatures.

Using electric spark is a good choice, as it can process micro holes with a minimum diameter of 0.15mm. However, the micro hole wall will leave a recast layer, which will affect the service life of the micro hole and deteriorate the surface quality of the micro hole wall;

Using mechanical drilling, firstly, the drill bit is very easy to break, and secondly, burrs will be left at the outlet of the micro hole, which will affect the final assembly effect.

.JPG)

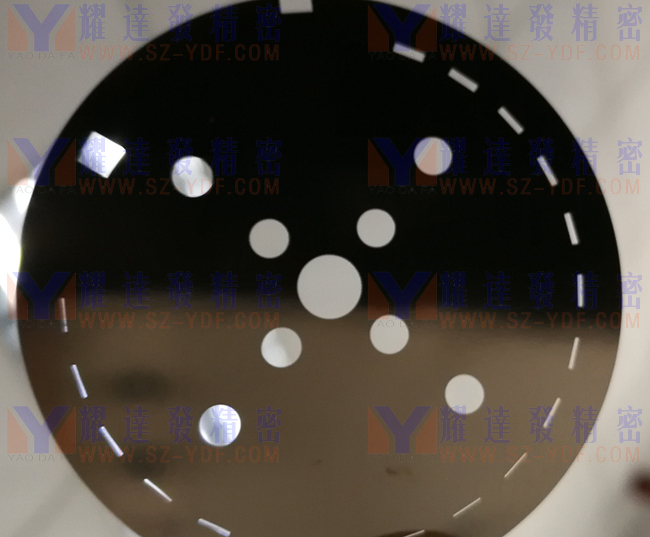

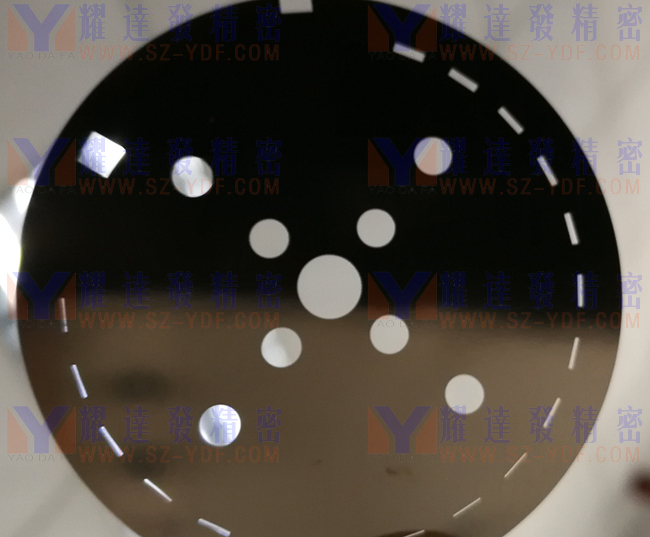

These micro holes can only be seen under a high-powered microscope, and many of the determining factors for micro drilling are similar to standard sized drilling processes. Whenever evaluating a new task, Yaoda Fajing Technology Co., Ltd. must first determine the most effective hole machining method. This largely depends on the type of machined parts, inner hole diameter, geometric shape, dimensional accuracy requirements and depth, batch size of machined parts, and the original machining method used.

Hand controlled machine tools equipped with microscopes are often used for scientific research projects, small batch production, or for machining only a few tiny holes. Some manufacturers dedicated to the development of micro hole machining machines mostly offer manually controlled machine tools, which can be traced back to the 1930s.

Yaodafa Precision has been engaged in the research of etching technology for micro hole processing for more than 10 years, and has accumulated some experience in processing micro holes. We process micropores through chemical etching.

.jpg)

The following are some important processes in micro hole processing

1. Cleaning process before micro hole processing

The process before etching micro holes in stainless steel or other metals is a cleaning treatment, mainly used to remove dirt, dust, oil stains, etc. from the surface of the material. Whether this process is well completed is the key process to ensure good adhesion between the film or screen printing ink and the metal surface. Therefore, it is necessary to thoroughly remove the oil stains and oxide film on the micro hole processing surface. The oil removal plan should be determined based on the oil contamination of the workpiece, and it is best to perform electrolytic oil removal before screen printing ink to ensure the effectiveness of oil removal. The best etching solution should also be selected according to the type of metal and the thickness of the oxide film to ensure a clean surface. Before screen printing, it needs to be dried. If there is moisture, it will also affect the adhesion of the ink, and even affect the effect of subsequent pattern etching, even causing distortion and affecting the etching effect.

2. Apply dry film or screen printing ink photosensitive adhesive layer

According to the actual product material, thickness, and precise width of the graphics, dry film or wet film silk screen printing is used for confirmation. For different thicknesses of products, when applying the photosensitive adhesive layer, factors such as the etching processing time required for the product''s graphics should be considered in order to produce a thicker or thinner photosensitive adhesive layer, so as to achieve good coverage performance and high clarity of the micro hole processed patterns.

3. Drying

After applying film or rolling screen printing ink, it is necessary to thoroughly dry the photosensitive adhesive layer to prepare for the exposure process. At the same time, it is necessary to ensure that the surface is clean, free of adhesion, impurities, etc.

4. Exposure

This process is an important step in micro hole processing, and the amount of exposure energy will be considered based on the thickness and precision of the product material. This is also a reflection of the technical capability of a micro hole processing and etching enterprise. The exposure process determines whether etching can ensure good dimensional control accuracy and other requirements.

5. Development

After the surface photosensitive adhesive layer of microporous processing is exposed, the graphic adhesive layer is cured on the metal plate after being illuminated. Afterwards, the parts that are not needed in the graphic, that is, the parts that need to be corroded, need to be exposed. The development process also determines whether the final size of the product can meet the requirements. This process will completely remove the unnecessary photosensitive adhesive layer covering the product.

6. Etching or corrosion process

The most critical process is after the pre production process of the product is completed. Chemical etching will be carried out. This process determines the key process of whether the final product is qualified. The entire process involves parameters such as the concentration, temperature, pressure, and speed of the etching solution, which collectively determine the quality of the product.

7. Film stripping

After etching, the surface of the product is still covered with a layer of photosensitive adhesive layer. This process requires removing the photosensitive adhesive layer on the surface of the product after micro hole processing. Due to the acidic nature of the photosensitive adhesive layer, the vast majority of them use acid-base neutralization method for swelling, overflow water washing and ultrasonic cleaning to remove the surface photosensitive adhesive layer. This process mainly prevents the residue of photosensitive adhesive.

After the film is removed, the remaining tasks are inspection and packaging. The size inspection ensures that no defective products are released into the hands of customers.

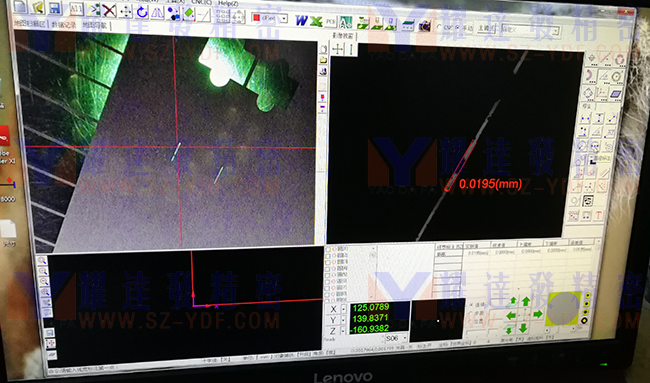

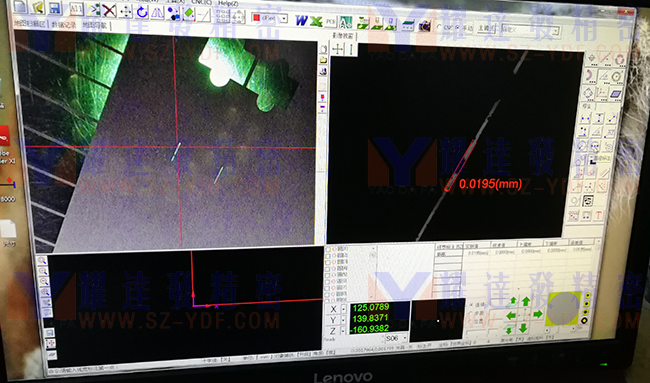

The micropores we process have a minimum pore size of 10 microns and a pore wall roughness of 0.02. The depth depends on the material thickness and pore size, and should not exceed 1mm without burrs.

I hope to work together with colleagues to improve the micro hole processing technology and make my own contribution to the mechanical manufacturing industry of our country. You can discuss with me, and I am also very willing to share with everyone my personal feelings about micro hole processing. Email: ly@sz-ydf.com .

Finally, I hope that our country''s micro hole processing technology can catch up with foreign countries.

Yaodafa Precision is a professional etching enterprise that provides micro hole processing. Our micro hole processing technology is advanced and can be improved with etching and laser technology to provide stainless steel micro hole processing services

Richard.Liu/刘家成

+86 180 2542 8186(wechat)

深圳市耀达发精密科技有限公司

Shenzhen Yaodafa Precision Technology Co., Ltd.

E-mail: LJC@SZ-YDF.COM

English website:http://www.ydf-seiko.com/

Shenzhen Address:203, Building 13, Dawangshan Second Industrial Park, Shajing Street, Bao''an District, Shenzhen , China

——Design and sales of metal accessories, metal finished products

——One Stop Solutions Provider Of Your Metal Precision Parts

Next:Corrosion process flowPrevious:Etching of lead frame

正在载入评论数据...

.jpg)